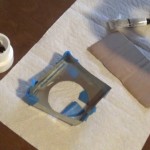

After the Radar Eye is cut, it needs to be bent into shape and the seams need to be bonded together with JB Weld, The center of the eye piece must be rolled and shaped into a circle. This is also where I cut out the side portion of the Radar Eye.

The materials I used are JB Weld, a PVC coupling to shape the inside cylinder, toothpicks, and blue tape.

Once the Radar Eye is bent into shape, it must be held together with tape and clamps so it does not come apart. The tape was used on the corner seams and for the bottom piece to hold them in place. The JB Weld was mixed per its directions and placed on all the seams. I allowed it to dry for at least 24 hours for maximum strength. This is only the initial bond since you may have to break some of the bonds apart to get a better hold in certain areas.

Next, the center piece is rolled around a PVC coupling to get the round shape. The eye circle is supposed to be 3″ in diameter, so I used a smaller circle since most metal likes its original shape. I rolled the metal around the PVC on the small section and it unrolled almost perfectly for the shape I needed. I put some tape on the shaft of the C-clamp so the JB Weld won’t stick by accident.

I then cut the final shape of the side panel.