The PSI Housing from PVC Coupler and Cutting Board

In order to make the PSI LEDS diffuse, we first need a housing to put them in. The back PSI hole is larger than the front, so an 1.5 ID PVC coupler is used for both front and back. The size does not matter since the light will look the same regardless of the size of the coupler.

A bead of hot glue is first applied to the inside of a 1.5″ PVC Coupler.

The PSI Electronics is than dropped inside of the PVC and held in by the hot glue. Be careful when you place this in. The LEDs are placed downwards so make sure they do not get damaged by the inner edge of the coupling.

Two cotton rounds are placed inside of this to diffuse the light from the LEDs so they appear as one color and not separate bulbs.

Another bead of hot glue is placed on the top of the PVC housing where the cotton rounds sit. Place the cutting board circle on the glue and hold until glue sets.

Hook the PSI up to the electronics to see how it looks!

Craft Spheres Made Into Holoprojectors Part II.

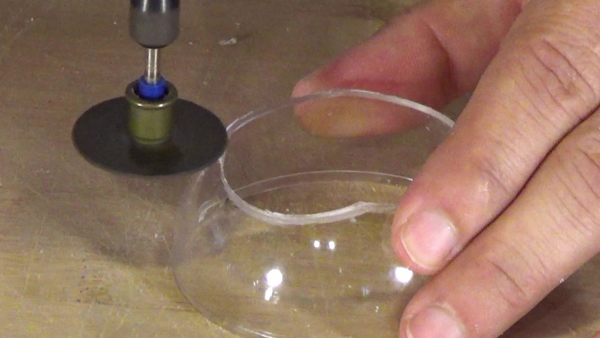

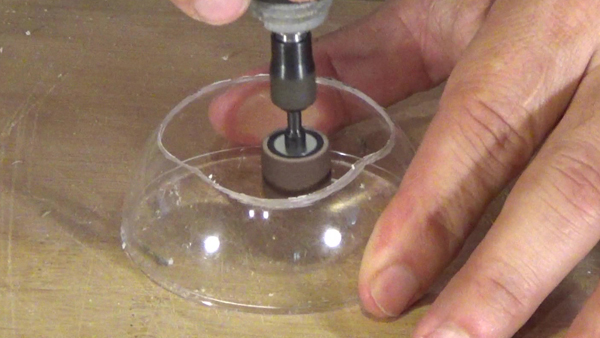

In Part I, I built the ball section of the Holoprojector, and in this part I will show you how I constructed the cowel section of the Holoprojector. It requires a bit of patience and some interesting tools. The hardest part is to find the center of the sphere. Here is the same video as in the previous post, were we left off at the 4:34 mark.

You will need a set of friction dividers to do this with my method. There are 4 large holes to be drilled through the backside of the sphere to get the proper dimensions of the Holoprojector. Although these are a bit bigger than spec, noone will really notice anything.

The first step is to find the center of the sphere and make marks 1/4″ in 4 quadrants. To make sure the marks are in the right spot, use the friction dividers spaced out at 23/64″ and draw semi circles to until they make an “x” on each of the spots marked.

Once the pilot holes are drilled, we enlarge them slowly with bigger bits. A 1-1/2″ hole saw is used on the concave side of the sphere with pilot bit that fits the hole saw. Slowly drill through this and don’t hurt your hand doing so. Do this for all 4 holes.

After it punches through, two raised portions must be made flat as the originals only have two flat spots. Once flattened, the inside is sanded smooth and everything can be assembled and painted how you like. It might be easier to paint after it is assembled. If you are making static Holoprojectors, gluing first is a better option.

Based on if you want the Holo to move or not will determine how you put them together. I have two static and one on a servo with an up/down motion. Each will need to be assembled differently.

Up next is the final assembly with lights, mounting and a servo.